[products]-

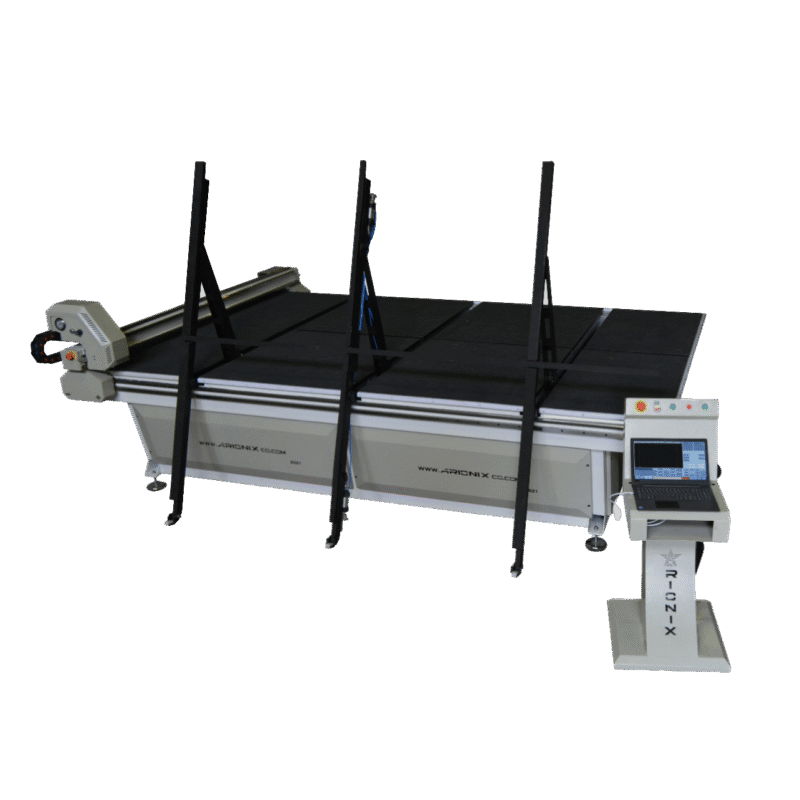

CNC Glass Cutting Machine

The Arionix CNC Glass Cutting Table, with its unique design, enables precise cutting of various types of glass and mirrors in different sizes and thicknesses.This machine is equipped with:Mechanical system for sheet loading and positioning

Automatic glass scanning and positioning system

High-precision cutting head with third-axis scoring wheelPressurized oil reservoir for superior cutting qualityBreakout system (breaker) in both longitudinal and transverse directionsAir flotation system for smooth, frictionless glass movement on the tableDedicated CNC software for layout design and cutting optimizationWith its robust structure and availability in different sizes, this machine is perfectly suited for a wide range of applications in the glass and mirror industry. -

CNC Glass Engraving Machine

Specifications:Working area: 150 × 300 cmLinear movement speed: 40 m/minSpindle power: 6 kWSpindle speed (RPM): 6000Enclosure: Fully insulated triple-layer fiberglass (first time implementation)Vacuum suction: 120 m³/h water-based system for secure workpiece holdingAxis drives: Servo motors with ball screw power transmissionController & software: Iranian-made RADONIXOptional W-type configuration availableCapabilities: Master engraving & detailed engraving (Ingraving)Build quality: High-grade construction, competitive with imported machines -

Proload CNC Glass Machine

Iran’s first fully automated glass cutting table with advanced engineering design

Robotic vacuum technology for hands-free glass loading and enhanced operator safety

Working dimensions: up to 244 × 366 cm, thickness up to 10 mm

High precision and cutting speed, performance comparable to imported machines

Easy mobility within the workshop for faster handling and operations

Simple CAM option for optimized layout and reduced material waste

Glass detection sensor and bilingual software (Farsi & English – Radonix) for easy operation and cutting path design

-

Vacuum Press Machine

Vacuum Press – Available in Three Models: Elevator, Box, and Sliding Rail

Technical Specifications:

Working dimensions: 140 × 300 cm and 120 × 250 cm

Radiant heating elements for efficient heat transfer and higher energy performance

100 m³/h vacuum pump for improved suction and material hold

Automatic wrinkle remover for smooth pressing results

Operation modes: Manual and semi-automatic PLC with programmable control for optimized production processes -

CNC Router for Wood and MDF

:Specifications

Working area dimensions (three sizes):183 × 366 cm,210 × 366 cm,122 × 244 cm.Three-axis operation (XYZ).Servo motors on all axes for precise motion control.Power transmission: Helical gears and ball screws.Spindle: 24,000 RPM for high-efficiency material removal.High-quality linear rails and carriages for smooth and accurate movement.Worktable with suction (vacuum) system for secure workpiece holding.Robust structure with stress-relieved frame for stability and durability.Radonix controller with continuous technical support.